Tech|Tips – 3DL: Diagnosing a Unique Problem

Recently I visited a fixture manufacturer that I had not been to in quite some time. The problem as described over the phone was “worms” under the 3DL in the profile of raised panel cabinet doors. Upon arriving at the plant I witnessed something I had never seen in my 20+ years in this business.

Though this was a new one to me my thoughts immediately turned to the vacuum system. Maybe the vinyl was floating over the profile just before pressure was applied causing the 3DL to wrinkle in such an unusual pattern? Several tests and checks later and still no solution.

Finally, I took one of the doors and peeled the 3DL back to see what it looked like under the wrinkle. Seeing that the MDF had split in the core, I felt completely lost. Was this poor board quality? Even if it was, would compressing it cause it to split? One thing seemed certain at that point. There wasn’t going to be a quick solution.\

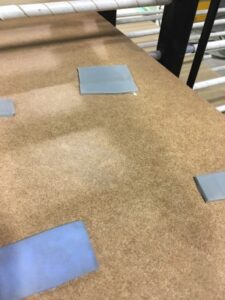

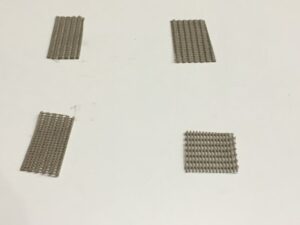

Looking around in bewilderment, something caught my eye that lead to a surprisingly simple solution. I saw a pedestal with anti-slip pads made of scrap 3mm thick membrane material.

The thickness of these pads meant the MDF core was flexing to the point of splitting in the profiles. Once replaced with standard cabinet liner, the problem was solved.

Next up: Ways to recycle scrap membrane material.

Bill Formella is President of Formella Contour Solutions and is the owner and moderator of the LinkedIn group Membrane Pressing & 3D Laminating Design. You can reach Bill at bformella@formellacsi.com. For more tips and ideas, follow us on Facebook and Twitter.

Looking for More Information?

Check out our Resources or Contact Us