Reusable Vacuum Bagging’s Specific Industries

Reusable Vacuum Bagging

For the best bagging materials, you’ve found the right page. With the precision of German design, Smartech offers you the best in industrial bags that will set your business and projects apart. Steinbach products are easy to use and offer unparalleled durability.

We know that your production has specific needs. The materials we provide you must be strong, long lasting, and fit for your task. That’s one reason why Smartech specializes in technical applications – it allows us to hone our products to give you the maximum performance you need in a reusable vacuum bag.

Your Vacuum Bagging Process is Important To Us

Your end product depends on the excellence of your bagging material.

We stock a wide variety of bagging material, so you can start your project immediately. Custom orders have quick lead times as well.

Don’t be shy if you’ve got a question about the right material for your process. Call us now at 704-362-1922!

About Vacuum Bags

Believe it or not, you can make a vacuum bag out of anything.

There are only three essential requirements:

1. That the bag be strong enough to create a vacuum.

2. That is be supple enough to mold to the part it’s bagging.

3. That it maintain these characteristics under high temperatures.

However, bags must also withstand all of your handling at layup, not wrinkle, provide a complete seal and conform to the deepest channels in a part. Steinbach’s high elongation materials virtually eliminate bridging without creating folds,

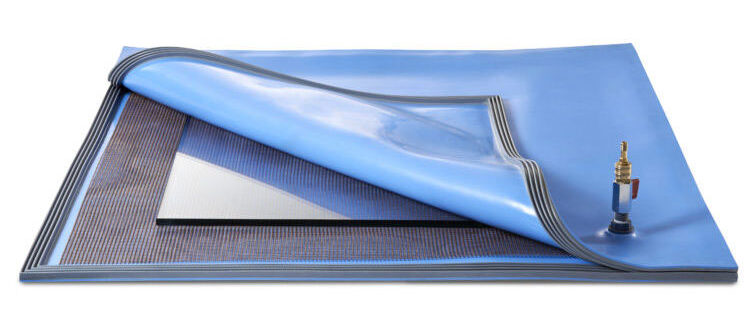

Our Reusable Bags

Steinbach’s new reusable bags offer a great improvement over single-use bags by helping you save money, time and resources.

With no pleating necessary, Steinbach bags allow you to complete more projects quickly with less skilled labor.

We only use the highest strength silicone materials, which can sustain perfect negative pressure and withstand temperatures of nearly 400 degrees Fahrenheit.

Our bags are always made to your custom specifications and are open on all four sides. Steinbach’s material widths will cover the majority of industrial applications, and their high elongation mixtures will help you avoid bridging.

We help you by providing unique options tailored to your application. Let us show you the power and utility that comes from Steinbach’s silicone reusable vacuum bagging.

Advantages of Reusable Vacuum Bags

Enjoy reduced cost use, fewer expendable materials and waste products, savings in labor, minimal creative steps, increased part consistency and complexity. See our itemized list of material and product specs.

Our silicone bags are available in a variety of durometers with smooth or textured surfaces. Vertical or horizontally oriented vacuum valve fittings, as well as thermo-couple pass-through valves provide the options your application requires.

You can enjoy all the money and time saving benefits of our progressive materials and quality construction right now. Just call us today!

Vacuum Bagging FAQs

How are Steinbach Vacuum Bags different from spray-on vacuum bags or silicone counter molds?

These have similarities, but the Steinbach Vacuum Bags offer more advantages! Our engineered silicone bagging materials perform the same function as an RVB or silicone counter mold. However, Steinbach’s pre-cured calendared material is more durable and easier to use than the brush or spray applied bag systems. Also, our high elongation materials will form to all the but the most severe profiles and are not limited to a single shape like a counter mold is.

What Difference Does The Color Make?

The color is really just to make it easier to differentiate between different material durometers. Many of our composite industry customers appreciate Steinbach’s translucent silicones to see what’s going on underneath during their forming and infusion processes.

Looking for More Information?

Click the button below or get in touch with one of our locations