Glass Lamination

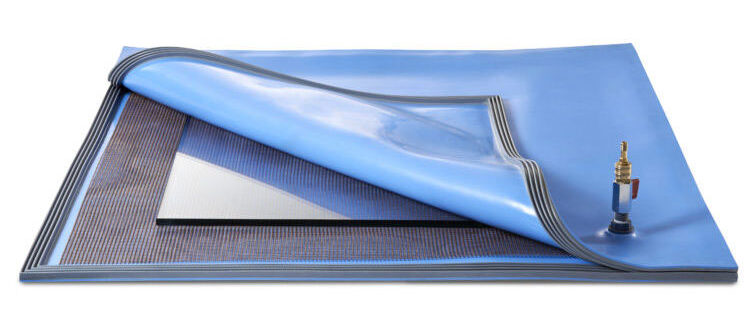

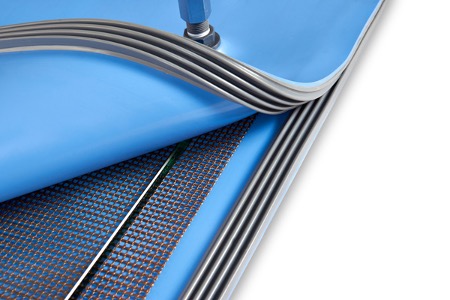

Steinbach’s reusable vacuum bags designed specifically for glass lamination ovens are durable and have proven to be more affordable than going back to the oven manufacturer for replacements. Steinbach vacuum bags are custom made to your exact production requirements. A choice of vertically or horizontally oriented vacuum valves fit any oven configuration, and thermal couple pass-throughs are also available.

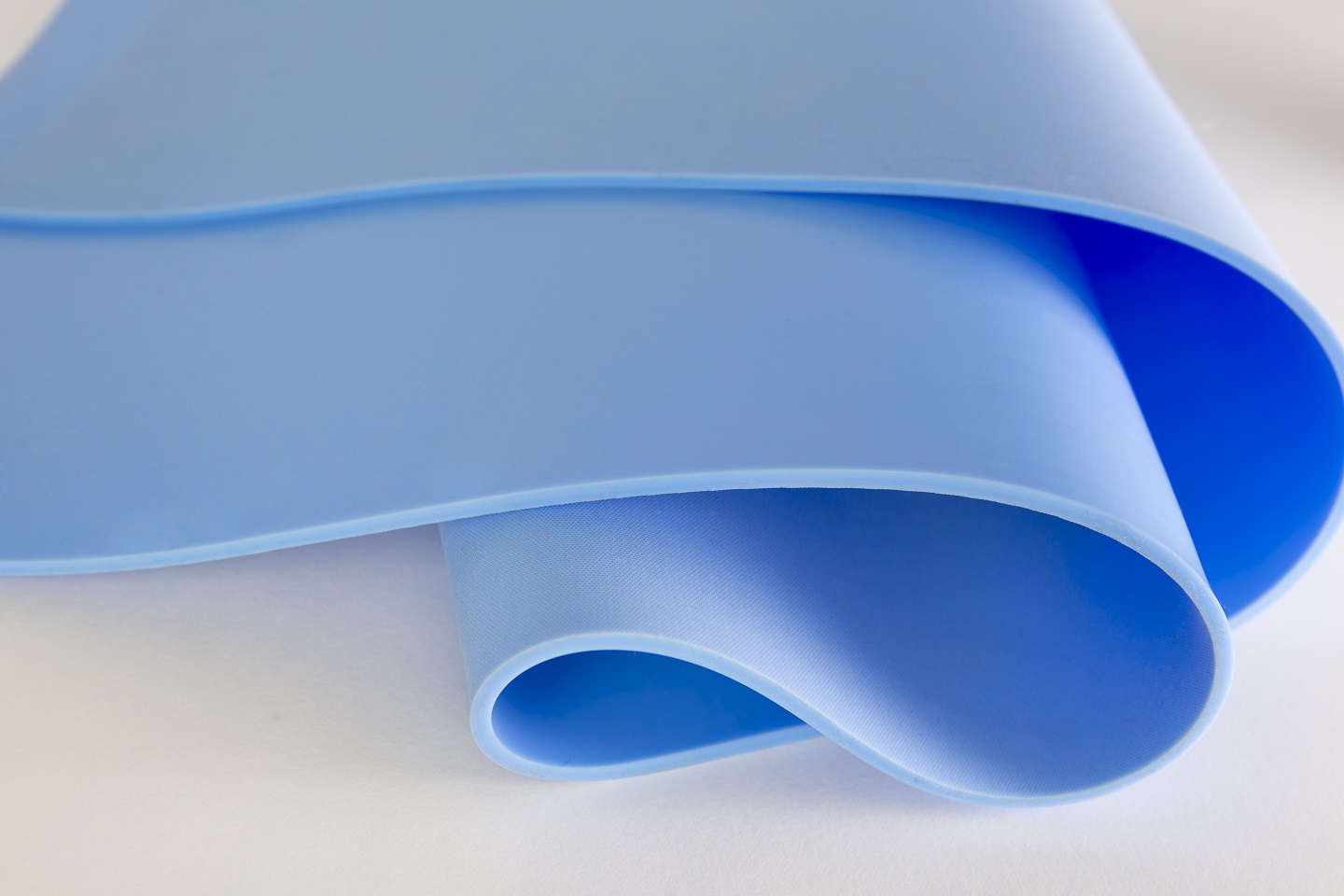

In addition to silicone membranes, we offer reusable vacuum bags, made of Steinbach silicone sheet with high elasticity and heat resistance up to 392°F (200°C). The 2-part bag opens on all four sides with a ribbed sealing edge that is perfect for flat glass components. The glass lamination is placed in the bottom half of the bag. Then the top half is put on and snapped in place. Thanks to the two-part bag (vs the traditional bag closed on 3 sides, where parts have to slide in), it is possible to place large, heavy glass plates, (such as laminated safety glass), into the vacuum bag using a suction cup manipulator. The vacuum valve is placed in the top half, which ensures easy handling.

More Information on Glass Lamination

Made-to-Size Products and Individual Advice on Site

We offer the 2-part vacuum bag and our membranes in different sizes. We manufacture our products according to your individual dimensions and would be happy to advise you on site. Stocking in our warehouse is also possible. Feel free to contact us. We look forward to providing you with comprehensive advice!

Looking for More Information?

Click the button below or get in touch with one of our locations