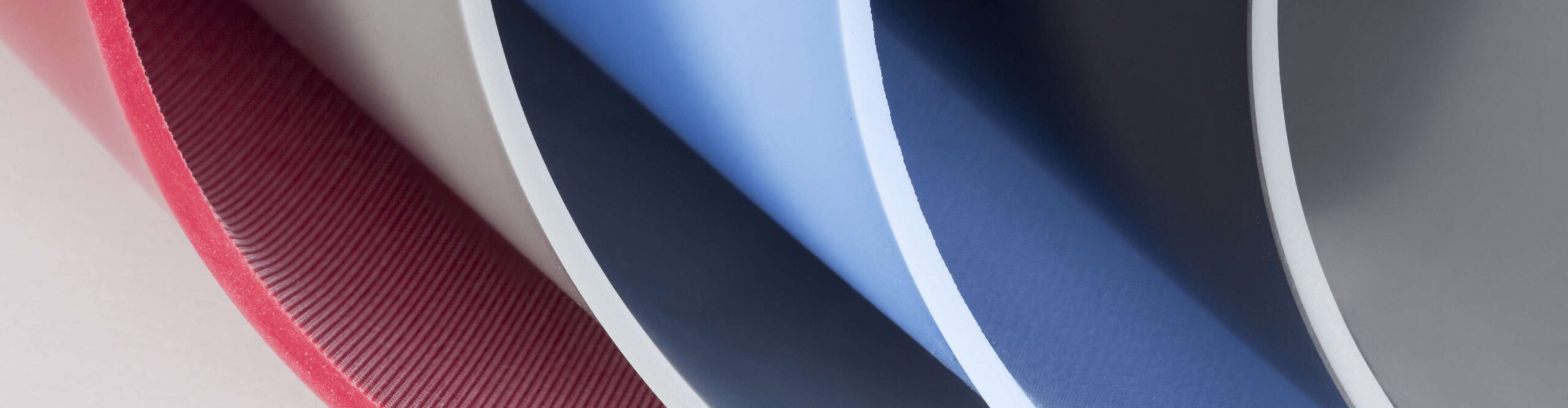

Diaphragms for the Solar Industry

Also called bladders, sheets, or membranes, the solar panel industry tends to use the term diaphragm.

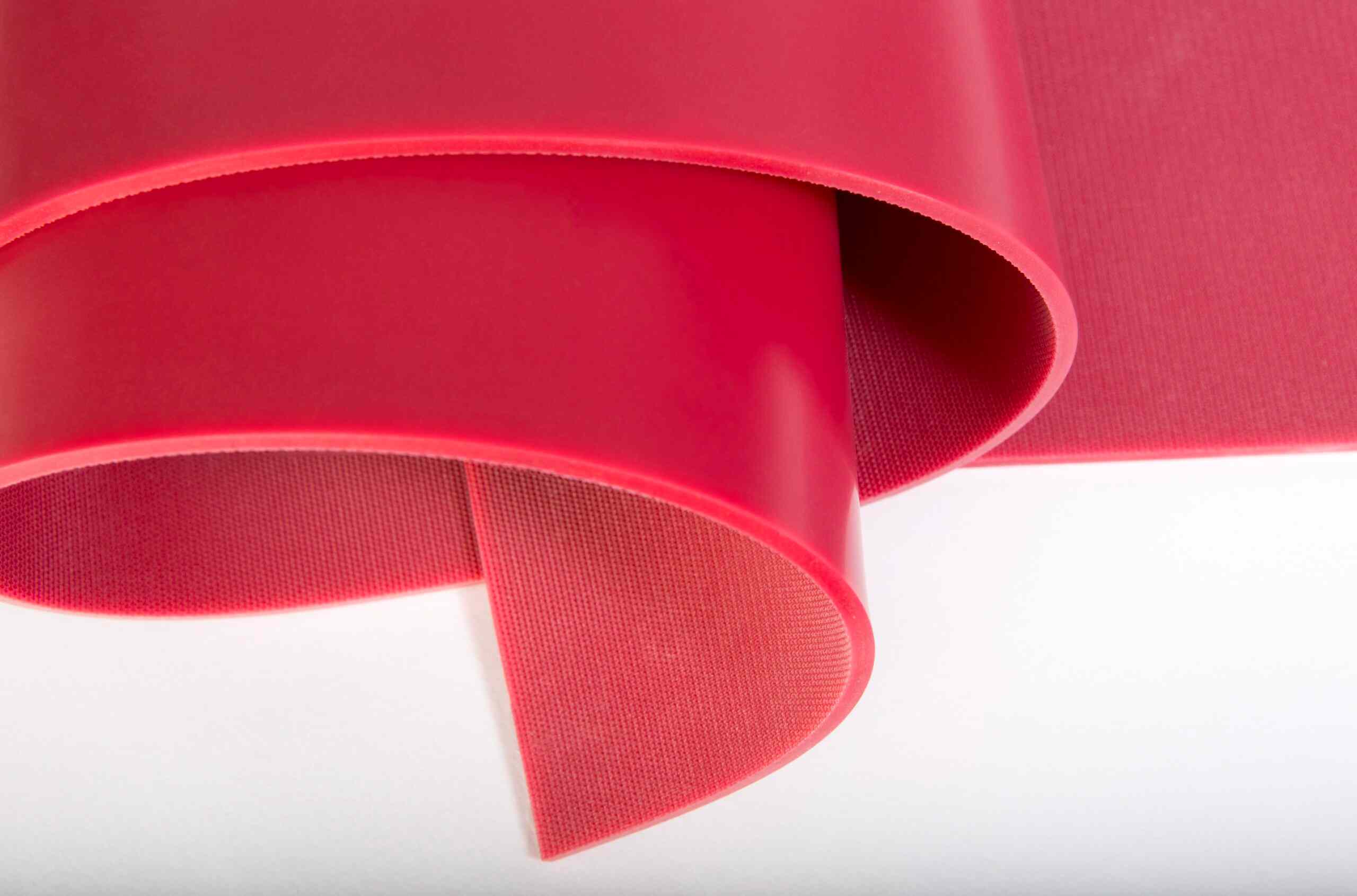

But whatever you call it, you want the best quality, long lasting sheet for your laminator. If EVA is your encapsulant, you should learn more about Steinbach’s Lamibran®. Specifically designed to resist the deterioration caused by EVA-outgassing, the Lamibran® is used around the world by the leading producers of both thin-film and crystalline solar panels.

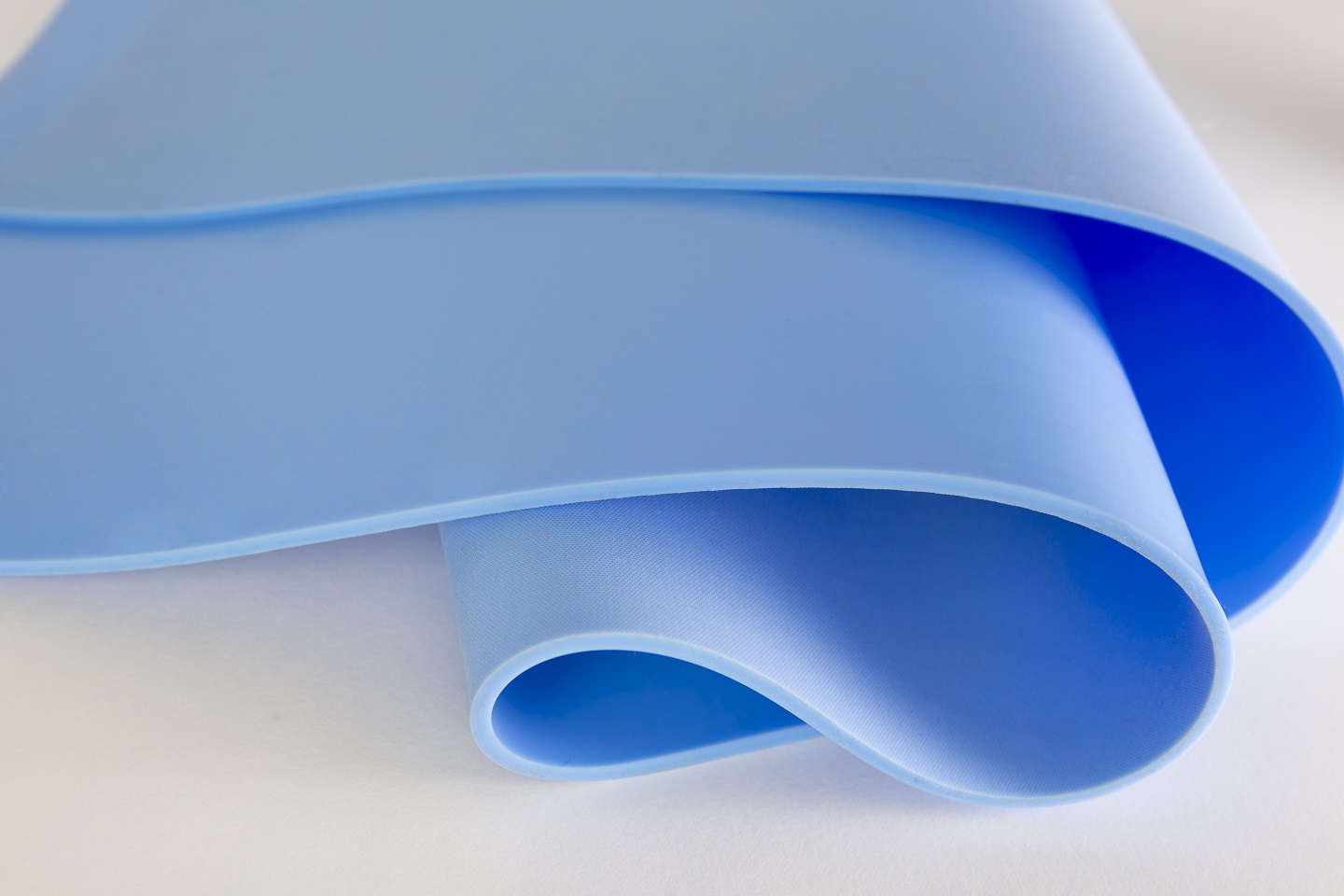

If your modules are glass/glass (rather than with a backer sheet), Steinbach’s grey, durometer 55 silicone is a popular option for many solar panel manufacturers.

Steinbach’s other silicone mixtures for the solar industry combine the required extra-wide sizes, tear resistance, and elongation to support the full range of module and laminator types in production world-wide. Call us and together we’ll figure out which option is the best for you!

Solar Diaphragm FAQs

What’s the best diaphragm for our application?

This is a big question and really best discussed together on the phone. Determining factors would include your type of encapsulant, composition of the modules, size of the modules, and type of laminator.

How long should a diaphragm last?

This also depends on your encapsulant and type of module. Give us a call to talk about your product and processes to determine what you should be getting from your diaphragm.

What can we do to extend the life of our diaphragm?

Consider protecting it with a layer of PTFE sheet between the modules and the diaphragm. We have several options for this. And if you’re encapsulating with EVA, we should discuss the Lamibran® diaphragm that is resistant to the outgassing from the EVA. The Lamibran® option may give you far better life than your current diaphragm.

Looking for More Information?

Check out our Resources or Contact Us