Reusable Vacuum Bagging for the Composite Industry

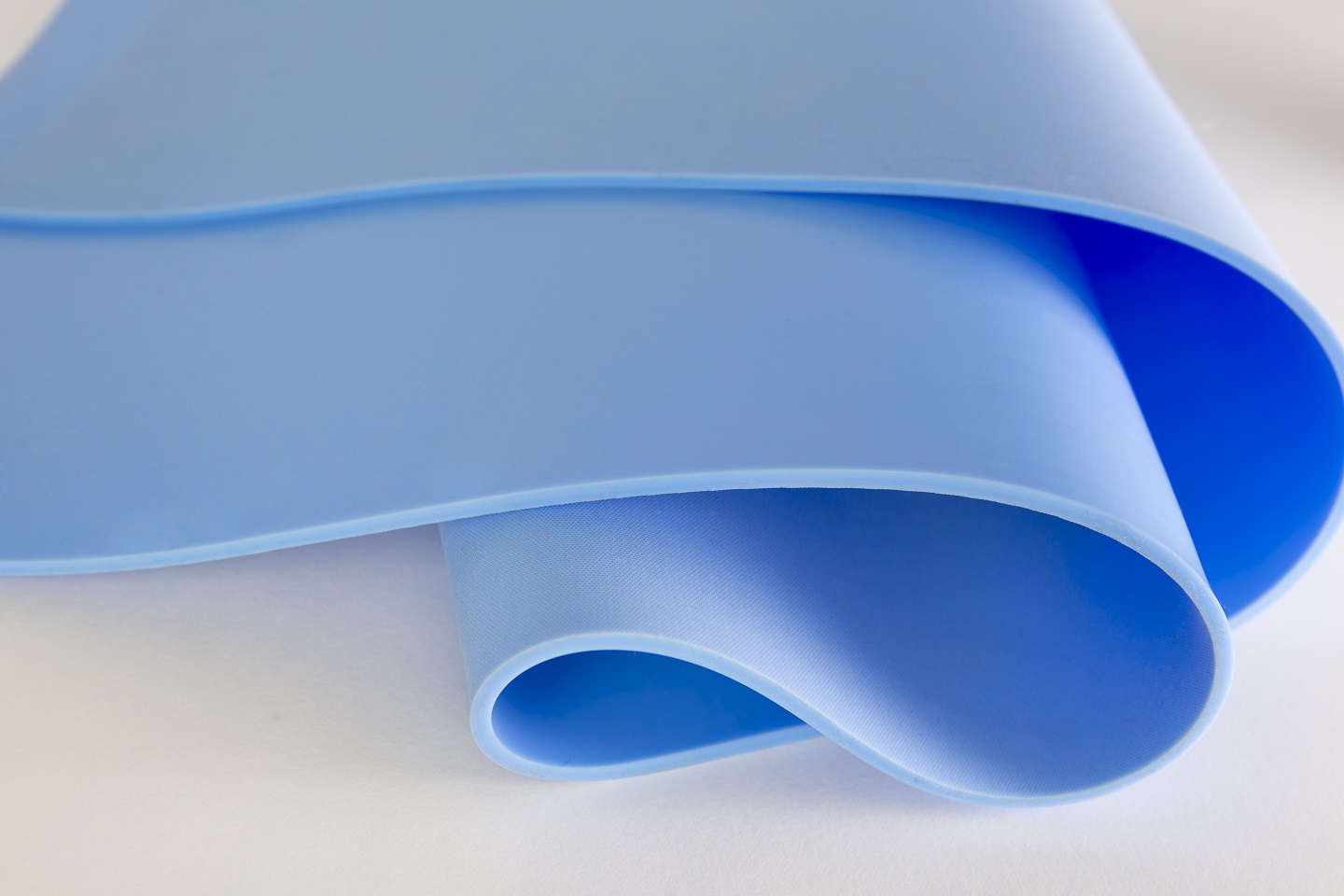

Smartech reusable silicone vacuum bags help composite manufacturers achieve consistent, high quality results. Each bag applies even pressure to improve resin control, fiber consolidation, and air removal. Designed for high temperature cure cycles and repeat use, these bags support production across aerospace, automotive, marine, wind energy, and industrial applications.

With custom sizes, material options, and valve configurations, Smartech vacuum bags reduce waste, speed setup, and deliver reliable performance in demanding composite production.

How Vacuum Bagging Works in Composite Fabrication

Vacuum bagging applies atmospheric pressure over a sealed composite layup by evacuating air through a vacuum pump. This pressure forces resin into fiber reinforcements, reducing voids, improving fiber-to-resin ratios, and delivering stronger, more consistent parts. A vacuum bag system includes release film, breather fabrics, and sealant tape to ensure airtight performance throughout the curing stage.

Supporting Your Composite Vacuum Bagging Process

Your end product depends on the excellence of your bagging material. This will determine the amount and uniformity of resin in your part, its consolidation and the elimination of voids.

That’s why we stock a wide variety of bagging material, to help with any job you undertake.

Don’t be shy if you’ve got a question about the right material for your process. Call us now at 704-362-1922!

How A Composite Vacuum Bag Should Work

In composite manufacturing, a vacuum bag is more than a simple enclosure. It is a critical tool that directly affects laminate quality, fiber consolidation, and surface finish during cure.

There are three essential requirements for a composite vacuum bag:

- Strong enough to hold full vacuum throughout the cure cycle.

- Flexible enough to conform to complex composite parts without bridging.

- Thermally stable at the elevated temperatures required for composite curing.

Beyond these fundamentals, a composite vacuum bag must also tolerate repeated handling during layup, resist wrinkling, form a reliable airtight seal, and fully conform into deep channels and tight corners. Smartech’s high-elongation bagging materials are engineered to minimize bridging while reducing the risk of folds that can imprint on the laminate surface.

How Our Reusable Bags for Composites Work

Steinbach’s new reusable bags offer a great improvement over throw-aways by helping you save money, time, and resources.

Complete more projects with easy repeatability.

We only use the highest strength silicone materials, which can sustain perfect negative pressure and withstand temperatures of nearly 400 degrees Fahrenheit.

Our bags are made to your custom specifications and are open on all four sides. Steinbach’s material widths will cover the majority of industrial applications, and their high elongation mixtures will help you avoid bridging.

We help you by providing options you just can’t find everywhere else. Let us show you the power and utility that comes from Smartech’s reusable silicone sheeting.

Advantages of Reusable Vacuum Bags

Reusable vacuum bags offer practical advantages in composite manufacturing where consistency, durability, and process efficiency directly impact production results.

Reduced Lifecycle Cost for Composite Manufacturing

Reusable vacuum bags lower material consumption and disposal needs, reducing long term operating cost across repeated production cycles.

Improved Part Quality and Resin Consolidation

Consistent vacuum pressure supports even resin distribution, helping minimize voids and improve laminate uniformity.

Sustainable Production With Less Waste

Reusable bagging reduces reliance on single use materials, supporting cleaner workflows and less production waste.

High Temperature Performance and Durability

Silicone materials maintain flexibility and seal integrity during high temperature curing and repeated use.

Custom Valve and Fitting Options

Valve orientation and pass through fittings are matched to part geometry and process requirements for better control.

Reusable Vacuum Bagging for the Composite Industry

Reusable Vacuum Bags Composites FAQs

What temperature can reusable vacuum bags withstand?

Smartech reusable vacuum bags for composites are made from high strength silicone materials that withstand temperatures approaching 400°F. This performance supports high temperature composite curing processes without loss of flexibility or seal integrity.

How do reusable silicone vacuum bags reduce costs?

Reusable silicone vacuum bags reduce costs by limiting the need for disposable materials and lowering labor associated with repeated layup preparation. In composite manufacturing, this supports repeatable production with fewer consumables and less waste.

Can these bags be tailored to large or complex parts?

Yes, Smartech vacuum bags for composites are fabricated to custom specifications and designed to conform to complex geometries. High elongation silicone materials help reduce bridging across deep channels and contoured surfaces.

What materials are best for high temperature composite curing?

Silicone is the preferred material for high temperature vacuum bags used in composite curing applications. Smartech uses high strength silicone formulations that maintain performance during repeated thermal cycles common in composite manufacturing.

Looking for More Information?

Check out our Resources or Contact Us