Reusable Vacuum Bagging’s Specific Industries

For the right reusable bagging materials, you’ve found the right place. With the precision of German design, Smartech supplies industrial vacuum bagging solutions built for consistent vacuum performance and dependable handling. Our Steinbach material partner supports silicone systems that are straightforward to use and made for demanding shop environments, including silicone vacuum seal bags configured for repeat production setups.

We know production requirements are specific. Your bagging material needs to be strong, long-lasting, and matched to the way you run your process. That’s why Smartech focuses on technical applications, so you can get the maximum performance from a reusable vacuum bag without overcomplicating the setup.

Support for Reusable Vacuum Bagging in Production

Your end product depends on the bagging material you run, especially once the process moves from one-off work to repeat cycles. Smartech focuses on technical applications, so the material and configuration fit your part, temperature range, and handling needs.

Have a question about what will work best in your process? Call 704-362-1922.

What to Expect from a Reusable Vacuum Bag

There are three core requirements.

- Strong enough to create a vacuum

- Supple enough to mold to the part

- Able to maintain performance under high temperatures

In real layup and handling, the bag should seal completely, avoid wrinkling, and conform to deep channels. Steinbach high elongation materials are described as reducing bridging without creating folds.

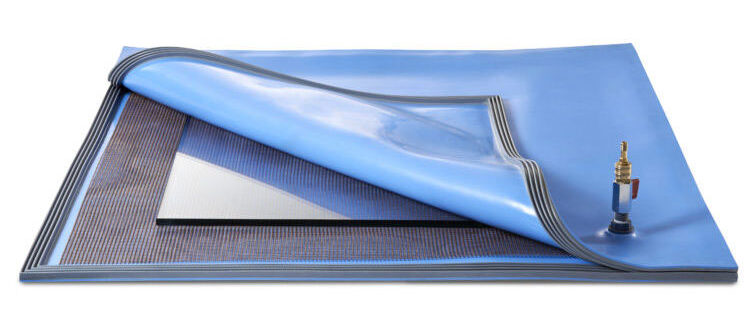

How our reusable silicone vacuum bags work

Steinbach reusable bags are designed to improve on single-use bags with time and resource savings. No pleating is necessary, which supports faster setup and repeatability with less skilled labor.

Smartech bags are made to your custom specifications and are open on all four sides. High-strength silicone materials sustain negative pressure and withstand temperatures of nearly 400 degrees Fahrenheit.

Durometer, Color, Surface, and Hardware Options

Silicone bags are available in multiple durometers with smooth or textured surfaces, allowing you to match flexibility and durability to the specific job.

Available silicone options

- Silicone, Translucent, Durometer 35

- Silicone, Translucent, Durometer 40

- Silicone, Blue, Durometer 50

- Silicone, Grey, Durometer 55

Hardware options include vertical or horizontal vacuum valve fittings and thermocouple pass-through valves. This is where silicone vacuum seal bags are configured to match equipment layout and process monitoring needs.

Advantages of Reusable Vacuum Bagging in Daily Production

Reusable bagging is chosen for production because it simplifies repeat work while improving consistency.

Key strengths

- Lower expendable use and waste through repeat bag use instead of single-use materials

- Faster setup with fewer prep steps and no pleating necessary

- More consistent outcomes from stable vacuum pressure across runs

- Better fit on complex parts with high elongation conformity that helps reduce bridging

- Built for demanding conditions with high strength silicone and stated temperature capability near 400°F

To compare options, review the itemized material and product specs in the industry sections, then choose the durometer and hardware configuration that best fits your workflow.

Vacuum Bagging FAQs

How are Steinbach vacuum bags different from spray-on vacuum bags or silicone counter molds?

These have similarities, but Steinbach vacuum bags bring clear practical advantages. The engineered silicone bagging materials perform the same function as an RVB or silicone counter mold, while offering easier handling and improved durability compared with brush or spray-applied bag systems. High elongation materials help the bag form to severe profiles and avoid the single-shape limitation of a counter mold.

Why use silicone for reusable vacuum bagging?

Silicone is used because it can stay flexible while maintaining vacuum integrity and handling repeated use. Smartech supplies reusable silicone bagging options across multiple durometers, with smooth or textured surfaces and hardware options like valve fittings and thermocouple pass-throughs to match production setups.

What difference does the color make?

Color mainly helps differentiate between material durometers. Many composite users prefer Steinbach’s translucent silicone to see what’s happening underneath during forming and infusion processes.

How should reusable bags be handled and stored between cycles?

Keep them clean, avoid sharp edges during handling, and store them in a way that prevents creasing or unnecessary stretching. Good handling habits typically extend service life and keep repeat setups consistent.

What temperatures can reusable vacuum bagging run at?

These reusable bagging materials are described to withstand temperatures of nearly 400 degrees Fahrenheit. Individual material options may list a maximum temperature up to 200°C or 392°F, depending on the product.

Read more: What Is the Temperature Range of Silicone Rubber?

How do I choose the right durometer?

Durometer helps balance flexibility and durability based on part geometry and handling. Options are available across durometers, including 35, 40, 50, and 55, so the material can be matched to your process.

Read more: How to Choose the Right Silicone Membrane Thickness

Still narrowing your spec for reusable silicone vacuum bags? Call 704-362-1922 and we will match material, durometer, and hardware to your process.

Looking for More Information?

Click the button below or get in touch with one of our locations