What Is Dye Sublimation & How Does It Work?

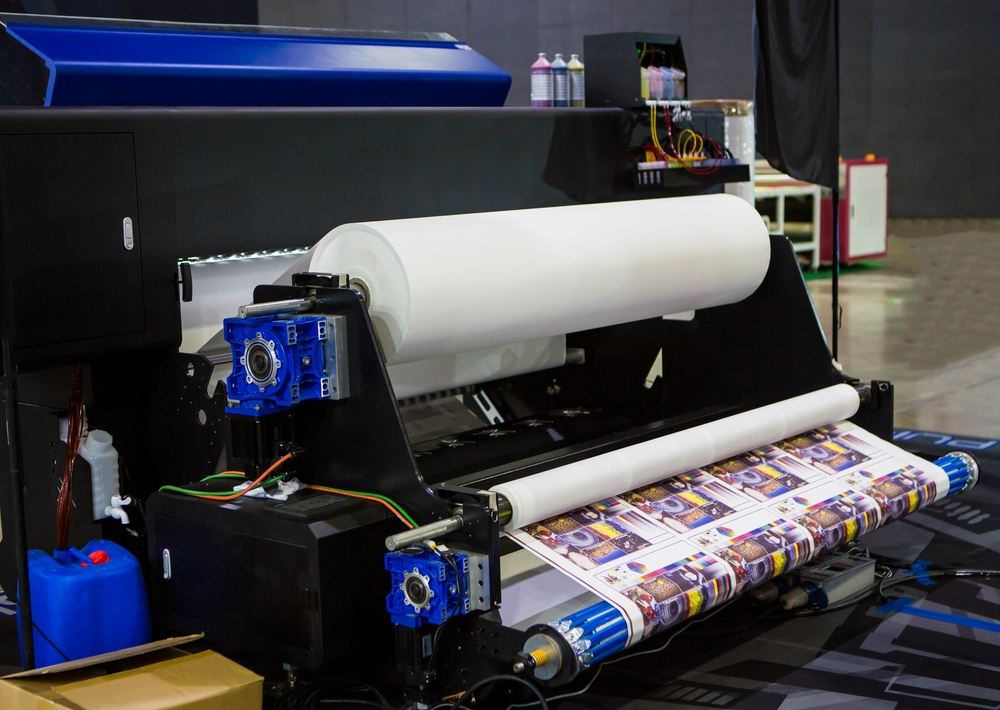

Dye sublimation is a type of printing process where heat is used to transfer dye onto a material. The process for dye sublimation involves printing a design onto a special transfer paper with dye-sublimation ink. Once a design has been created and printed on the transfer paper, this gets placed onto the material that will be printed and adhered using heat-resistant tape. The transfer paper and material go through a heat press which applies both heat and pressure to the transfer paper, which causes the dye to sublimate. During this process, the ink turns into a gas, and the heat encourages porosity in the material so the dye gas can penetrate the surface effectively. After a designated amount of time, the dye gas is able to effectively penetrate and bond with the material fibers before it solidifies. This is how dye sublimation makes the design become a permanent part of the material. Dye sublimation results in high-quality, vibrant prints that are long-lasting and can be used in a variety of contexts.

What Is Dye Sublimation?

The technology of dye sublimation establishes a process for transferring dye directly into the material, as opposed to traditional printing, where ink is applied to the surface. A dye sublimation printer is specifically designed to produce high-quality prints using this thermal printing technique. When the dye gets heated up, it begins to vaporize and turn into a gas. The gas then gets diffused onto the surface of the intended material and forms a bond, which results in a permanent print. Dye sublimation can be used to create and customize silicone and rubber membranes. Once the membrane gets coated with a special polymer that allows the dye to bond with the surface, the heat press will sublimate the ink onto the membrane. The process of dye sublimation can be used in a variety of contexts, including custom designs and the production of industrial components.

How Does Dye Sublimation Work?

Dye sublimation works on specially coated surfaces, including ceramics or metal, and can also be applied directly onto the surface of the fabric. Dye sublimation uses heat to transfer the dye onto the specified material and results in a print that won’t fade, peel, or crack over time. The process begins with creating a digital design that is then printed onto a special type of transfer paper that uses dye sublimation ink. The transfer paper is then secured onto the material that will be printed with a heat-resistant adhesive. Next, the transfer paper and material are placed into a heat press. The heat and pressure on the transfer paper cause the dye to sublimate, which means it turns into a gas. The heat from the press also opens the pores of the material, so the dye gas is able to penetrate the surface and bond to the material. During the cooling process, the dye gas re-solidifies and is now a permanent part of the material.

Where is Dye Sublimation Used?

Dye sublimation printing can be used for a variety of applications, including:

Promotional Items

Promotional items, including mugs, keychains, mousepads, and customized clothing, can all be created with dye sublimation printing. Dye sublimation for promotional items produces high-quality, long-lasting prints.

Signage

Signage, including banners, flags, and outdoor signs, can also be created using dye sublimation. This type of printing process results in prints that are durable and weather-resistant, which makes dye sublimation printing ideal for signs in heavy traffic areas or for outdoor usage.

Industrial Components

Industrial components, including keypads, overlays, and controls, can be produced using dye sublimation printing. Dye sublimation produces products that can withstand harsh industrial environments with durability and resistance.

What are the Benefits of Dye Sublimation?

There are several benefits of dye sublimation.

High Quality

Dye sublimation results in high-quality prints in exceptional detail and a wide range of color options. Dye sublimation can be used with even the most intricate of designs and offers precise color matching and results in no visible texture.

Durability

Dye sublimation prints are incredibly durable, which means they are incredibly resistant to issues like fading, cracking, or peeling. Even when used in high temperatures or harsh environments, dye sublimation prints offer long-lasting durability.

Versatility

Dye sublimation can also be used for printing on a variety of materials, including plastics, silicone membranes, rubber membranes, and metal. This type of printing can be used in a wide range of applications.

Customization

Dye sublimation is easily customizable, which makes it a great option for personalized items and designs with intricate details.

Eco-Friendly

Dye sublimation offers an eco-friendlier alternative to traditional printing modes and produces less waste. The process of dye sublimation also uses less energy and water, producing fewer overall emissions.

Choosing the Best Silicone Membrane for Dye Sublimation

Dye sublimation is a popular printing method with a wide range of benefits for silicone membranes and other materials. Choose the best silicone membrane for dye sublimation thanks to the high heat resistance and adhesive strength of silicone. The thickness and flexibility of silicone membranes can also impact the dye sublimation process. The quality of silicone membranes for dye sublimation helps ensure high-quality and long-lasting prints. Contact us today to learn more about our silicone membranes and other options available with Smartech.

Looking for More Information?

Check out our Resources or Contact Us