Membrane Pressing vs Vacuum Forming Pros & Cons

Choosing the right 3D lamination process for your project requires understanding the available options. Membrane pressing and vacuum forming are popular techniques that offer a durable way to laminate shaped pieces, particularly in the woodworking industry. While both methods share some similarities, they also have distinct advantages and disadvantages. Let’s delve into these processes to help you decide which best suits your needs.

What is Membrane Pressing?

Membrane pressing is a manufacturing process that uses positive pressure from above, as well as vacuum from below to form laminates onto 3-Dimensionally shaped parts. With membrane pressing, the flexible membrane applies pressure to a material such as wood veneer or laminate, pressing it onto a substrate. The membrane, usually made from silicone or natural rubber, ensures an even pressure distribution over the surface, allowing for intricate detailing and high-quality finishes. In addition, the membrane serves to transfer heat from the membrane press onto the part in order to ensure proper bonding of the adhesive used.

Common Materials Used:

- Wood veneers

- Thermoplastic Laminates (PVC, PET)

Common applications of membrane pressing include:

- Kitchen and bath cabinet doors

- Architectural elements such as decorative wall panels,

- Musical instruments (acoustic guitar bodies)

- Interior design features (decorative moldings)

Advantages and Disadvantages of Membrane Pressing

Advantages of Membrane Pressing

-

- Higher Production Numbers: Membrane press systems can be highly automated and have shorter cycle times than vacuum formers.

- Complex Shapes: Laminates highly detailed and intricate forms.

- Uniform Pressure: Ensures consistent pressure for a high-quality product.

- Heat Transfer: Ensures that the glue line has sufficient heat to bond completely.

- Material Versatility: Works with various wood veneers and thermoplastic laminates.

Disadvantages of Membrane Pressing:

- Higher Machinery Costs: Compared to vacuum forming, a membrane pressing system will be more expensive.

What is Vacuum Forming?

Vacuum forming, a simplified version of thermoforming, can operate with or without a membrane. The heat source tends to be lamp systems that create hotter and cooler spots on the lamination surface. Parts are placed in the vacuum former, the laminate sheet is placed over the entire lay-up table and heat is turned on when the former closes. Once the laminate is softened, vacuum is applied pulling the sheet onto the parts below. The most common material used is PVC.

Vacuum forming is a simple and cost-effective method suitable for producing low-volume parts with relatively simple geometries. Applications include:

- Kitchen and bath cabinets

- Point-of-purchase displays: signage to promote products at the point of sale

- Prototyping: creating quick and inexpensive physical models for design evaluation

Advantages and Disadvantages of Vacuum Forming

Advantages of Vacuum Forming:

- Cost-Effective for Small Batches: Lower setup and equipment costs make vacuum forming suitable for small to medium production runs.

- Versatility in Design: The process can handle a wide range of colors and textures, enhancing the aesthetic value of products.

Disadvantages of Vacuum Forming:

- Not Ideal for High-Volume Production: While suitable for smaller runs, costs can become prohibitive at larger scales.

- Material Restrictions: Limited to forming thinner materials, which may not be suitable for all applications.

- Detail Limitations: The level of detail achievable is less than in processes like thermoforming or injection molding, which may affect the final product’s precision.

Membrane Pressing vs. Vacuum Forming: A Side-by-Side Comparison

| Factors | Membrane Pressing | Vacuum Forming |

| Machinery Costs | Higher due to more complex equipment | Lower, suitable for smaller runs |

| Part Complexity | Allows for more intricate designs and complex shapes | Better for simpler shapes |

| Production Speed | Automated for high production numbers | Suited for lower-volume production |

| Detail and Finish | High-quality, seamless finishes | Limited detail and finish quality |

| Material Compatibility | Wide range of films and veneers | Various thermoplastics |

Membrane pressing is ideal for producing high-quality, intricate designs with a seamless finish, commonly used in the furniture and cabinetry industries. It involves higher tooling costs but also has high production speeds while offering exceptional detail and material versatility. Vacuum forming, on the other hand, is a simpler and more cost-effective method suitable for low to medium-production runs with simpler shapes. It has lower equipment costs. Use this comparison to determine which process best aligns with your project’s requirements.

Choosing the Right Process: Membrane Pressing vs. Vacuum Forming

When deciding between membrane pressing and vacuum forming, consider the complexity of the design and the desired surface finish. Membrane pressing is the better choice for achieving intricate details and high-quality finishes on materials such as wood or composites. It is particularly suited for applications like furniture and cabinetry where aesthetics and durability are paramount.

Vacuum forming, however, is more appropriate for producing parts with simpler shapes. This method excels in efficiency and cost-effectiveness.

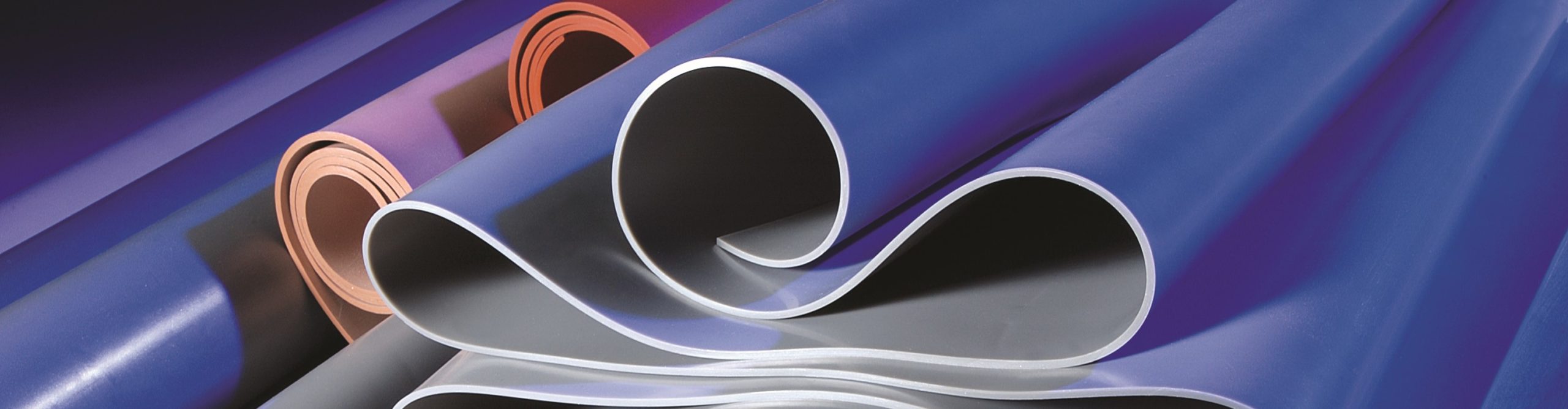

Steinbach Membranes: The Ultimate Choice for Membrane Pressing and Vacuum Forming

Both membrane pressing and vacuum forming rely on specialized membranes to achieve the desired final shape and surface finish. Steinbach Silicone & Natural Rubber Membranes, offered by Smartech, are designed to excel in these applications.

Steinbach membranes are renowned for their exceptional flexibility and durability, making them ideal for withstanding the pressures and temperatures involved in membrane pressing and vacuum forming processes. They are available in a variety of options, including smooth or textured silicone and matte natural rubber, to suit specific project requirements, such as achieving a high-gloss finish or minimizing surface imperfections.

Find the perfect Steinbach membrane for your membrane pressing or vacuum forming project! Browse options and contact us for assistance.

Looking for More Information?

Check out our Resources or Contact Us