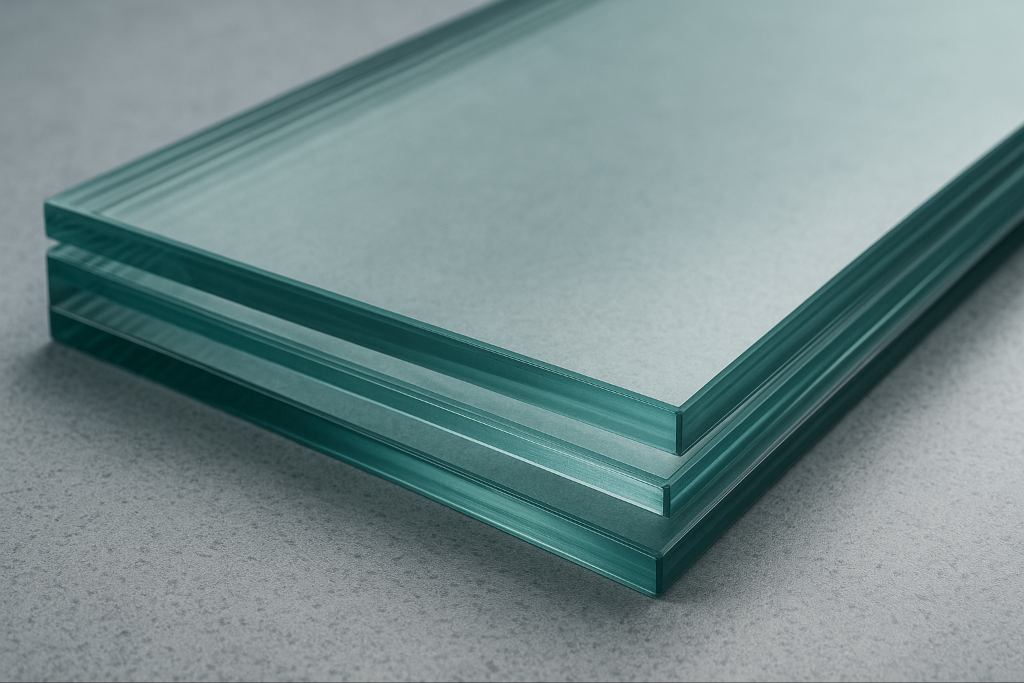

Laminated Glass Thickness Guide: Strength vs. Clarity

Thicker laminated glass offers a tangible boost in impact resistance while keeping visibility crisp under pressure. In settings where both strength and clarity are important, selecting the optimal balance of laminated glass thickness can make all the difference. Feeling confident in your choice means knowing how different thicknesses behave in real-world conditions, where use, safety, and performance are key considerations.

What is Laminated Glass and How is Thickness Measured

Laminated glass is created by bonding two or more layers of glass together with an interlayer, often made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). This design holds the glass together when broken, preventing dangerous shards from scattering. The interlayer also adds acoustic and UV protection, which makes laminated glass suitable for both safety and comfort.

Thickness is measured by adding up the combined layers of glass and the interlayer material. For example, a configuration labeled as 6.38 mm typically consists of two 3 mm glass sheets with a 0.38 mm interlayer. Industry norms often describe laminated glass thickness in this shorthand format, making it easier to specify and compare options across projects.

How Laminated Glass Thickness Influences Strength and Clarity

Thicker laminated glass serves a dual purpose, enhancing durability while also impacting visual quality. This balance matters when both safety and appearance are top priorities. What follows is a look at how thickness impacts both strength and clarity, so you can make informed choices that won’t compromise either.

How Thickness Supports Structural Strength

Thicker laminated glass offers greater resistance to breakage and improved ability to absorb impact. It performs well in demanding conditions, such as wind loads or physical force, making it ideal for items like building façades or protective barriers. Laminated windshields benefit too, as they stay intact on impact, reducing injury risk. This rugged behavior makes thickness a key factor where safety and durability count.

How Thickness Influences Clarity and Optical Quality

As laminated glass becomes thicker, a faint green or blue-green tint may appear, especially beyond 10 mm, along with slight edge haze or distortion. These effects are usually minimal but may be noticeable in applications that demand maximum visibility, such as storefronts or interior partitions. High-quality interlayers and precise manufacturing help retain clarity and consistent light transmission, even in thicker panels.

Application-Based Guide to Laminated Glass Thickness

Choosing the right thickness depends on the glass’s intended function. Different applications require different levels of strength and clarity, and industry standards guide each. Below is a breakdown of common uses and the recommended laminated glass thickness for each.

Residential and Commercial Windows

For standard windows in homes and offices, laminated glass with a thickness of between 6 mm and 8.76 mm is common. This range strikes a balance between safety and visibility, providing protection against impact while maintaining clear views.

Skylights and Overhead Glazing

Overhead installations typically require thicker glass, often ranging from 8.76 mm to 12.76 mm. This prevents failure from falling objects and adds reassurance in high-traffic or exposed areas.

Automotive Glass

Windshields typically use laminated glass with a thickness of 6.76 mm, providing durability while maintaining optical clarity for safe driving. Side and rear applications may vary, but follow similar requirements for impact resistance.

Safety and Security Glazing

For banks, storefronts, or facilities requiring high security, laminated glass can range from 12 mm to more than 20 mm, depending on the threat level. These panels provide resistance against forced entry or even ballistic impact, depending on construction.

Industry Standards and Testing for Laminated Glass Thickness

Meeting reliable performance benchmarks relies on trusted standards that guide testing and quality control. The following standards support safe, clear, and durable laminated glass by defining how thickness is tested and evaluated:

- ASTM C1172‑24: Sets quality benchmarks for flat laminated architectural glass, covering strength, security, and thickness combinations. Includes tests for impact, wind, and blast resistance.

- ASTM C1900‑24: Describes procedures for exposing laminated glass to both natural and accelerated weathering, guiding how long-term durability is measured. Short‑term tests suggest performance trends, but real insight comes with multi‑year exposure.

- Supplementary Methods (ASTM/ISO): Provides related testing methods for measuring haze, light transmittance, solar reflectance, and UV exposure. These help pinpoint issues like yellowing, clarity loss, or haze over time.

Take Your Laminated Glass Quality Further with Smartech

Choosing the right laminated glass thickness is crucial in striking a balance between strength and clarity, while consistent production relies on reliable lamination support. Softer interlayers prevent panels from shattering, and the correct thickness ensures that both safety and transparency work together.

Smartech brings precision and consistent performance to glass lamination with silicone membranes designed for durability and reliability. These membranes offer excellent heat resistance, flexibility, and long life, even under high-pressure autoclave conditions. We offer both smooth and textured silicone options to match different production needs, and we maintain rigorous standards for performance, durability, and fast delivery.

Contact us today and let Smartech help you achieve stronger, clearer laminated glass with consistent results and dependable support.

Looking for More Information?

Check out our Resources or Contact Us