Improving Manufacturing Efficiency with High-Temperature Insulation

In a competitive manufacturing environment, efficiency is paramount. Companies across industries continuously seek ways to reduce costs, increase output, and enhance safety without sacrificing product quality.

One of the most effective solutions can lie in optimizing thermal management through high-temperature insulation. This approach not only protects equipment and workers but also streamlines operations and improves energy efficiency.

The Importance of Temperature Control in Manufacturing

Many manufacturing processes—such as those in the automotive, aerospace, glass, and steel industries—require extreme heat to transform raw materials into finished products. Managing these high temperatures effectively can make or break efficiency. Without adequate insulation, heat loss becomes a major concern, leading to higher energy consumption, increased maintenance needs, and safety hazards. High-temperature insulation addresses these concerns by stabilizing the heat flow, allowing manufacturers to maintain consistent production speeds while minimizing energy waste.

Energy Efficiency and Cost Savings

Energy consumption is one of the largest operating expenses for manufacturers, particularly those relying on high-temperature processes. High-temperature insulation reduces the amount of heat lost to the surrounding environment, leading to significant energy savings.

This means lower fuel costs, reduced greenhouse gas emissions, and a smaller environmental footprint. Over time, these savings can accumulate to represent a substantial reduction in operating costs, giving companies a competitive edge.

Improved Equipment Longevity

Excessive heat can degrade equipment, leading to more frequent repairs, breakdowns, and costly downtime. High-temperature insulation helps to prevent unnecessary wear and tear by maintaining more stable operating temperatures and shielding equipment from thermal stress.

By protecting critical machinery, manufacturers can extend the lifespan of their equipment, decrease the need for expensive repairs, and minimize unplanned production halts.

Enhanced Workplace Safety

Maintaining a safe work environment is crucial for any manufacturer. High-temperature processes can create hazardous conditions if not managed properly. Workers exposed to high heat face the risk of burns, and overheated equipment can lead to accidents. High-temperature insulation provides an extra layer of protection, keeping surface temperatures at safe levels and ensuring that workers are shielded from dangerous exposure. This not only improves safety but also reduces the likelihood of workplace injuries and associated compensation costs.

Product Quality and Consistency

Inconsistent temperatures during manufacturing can lead to defects and subpar products. High-temperature insulation ensures that heat is evenly distributed across equipment, which helps maintain product consistency.

Whether it’s maintaining the correct temperature in a furnace or ensuring a uniform heat treatment process, insulation ensures that products meet quality standards, reducing waste and rework, which can otherwise slow down production and increase costs.

Sustainability and Environmental Impact

With growing pressure on industries to adopt sustainable practices, high-temperature insulation offers an opportunity to improve energy efficiency and reduce waste. By conserving energy, manufacturers can significantly lower their carbon footprint, contributing to global efforts to mitigate climate change.

Additionally, many insulation materials are recyclable and durable, aligning with sustainability goals and helping manufacturers meet regulatory requirements on energy efficiency and environmental protection.

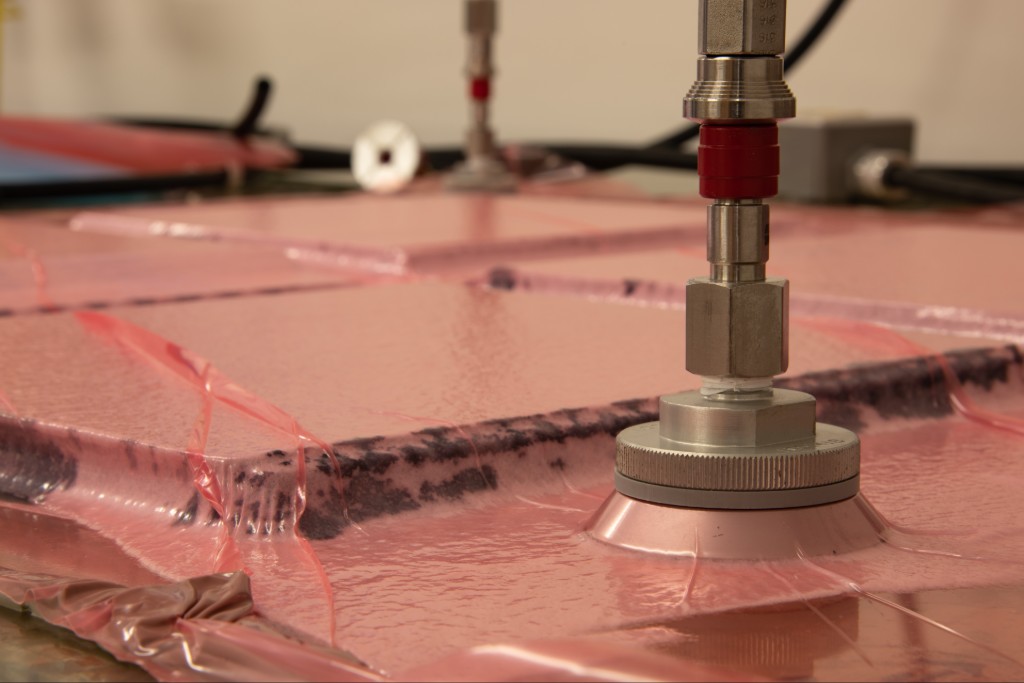

Choosing the Right High-Temperature Insulation

Not all insulation solutions are created equal. The choice of material, design, and installation method can vary depending on the specific requirements of the manufacturing process. Some common types of high-temperature insulation materials include:

- Ceramic Fiber: Lightweight and highly resistant to thermal shock, suitable for temperatures up to 3000°F (1649°C).

- Mineral Wool: Offers excellent fire resistance and soundproofing properties and is typically used for insulation in high-temperature pipes and vessels.

- Calcium Silicate: Commonly used in industrial processes due to its high strength and durability under extreme conditions.

- Microporous Insulation: Extremely lightweight with low thermal conductivity, suitable for confined spaces where weight and insulation thickness are critical factors.

Manufacturers need to assess their specific process needs, temperature requirements, and equipment specifications to select the optimal insulation material.

High-temperature insulation is a powerful tool in the quest for manufacturing efficiency. Investing in the right high-temperature insulation is not just a short-term fix but a long-term strategy for success in today’s competitive industrial landscape.

High Temperature Insulation from Smartech

At Smartech, we provide high-quality, high-temperature insulation solutions that can help you reduce energy costs, protect your equipment, and improve workplace safety. Our expert team is here to guide you in choosing the right insulation for your unique processes, ensuring long-term performance and sustainability. Contact us today to learn how we can help your facility run more efficiently and increase your bottom line.

Looking for More Information?

Check out our Resources or Contact Us