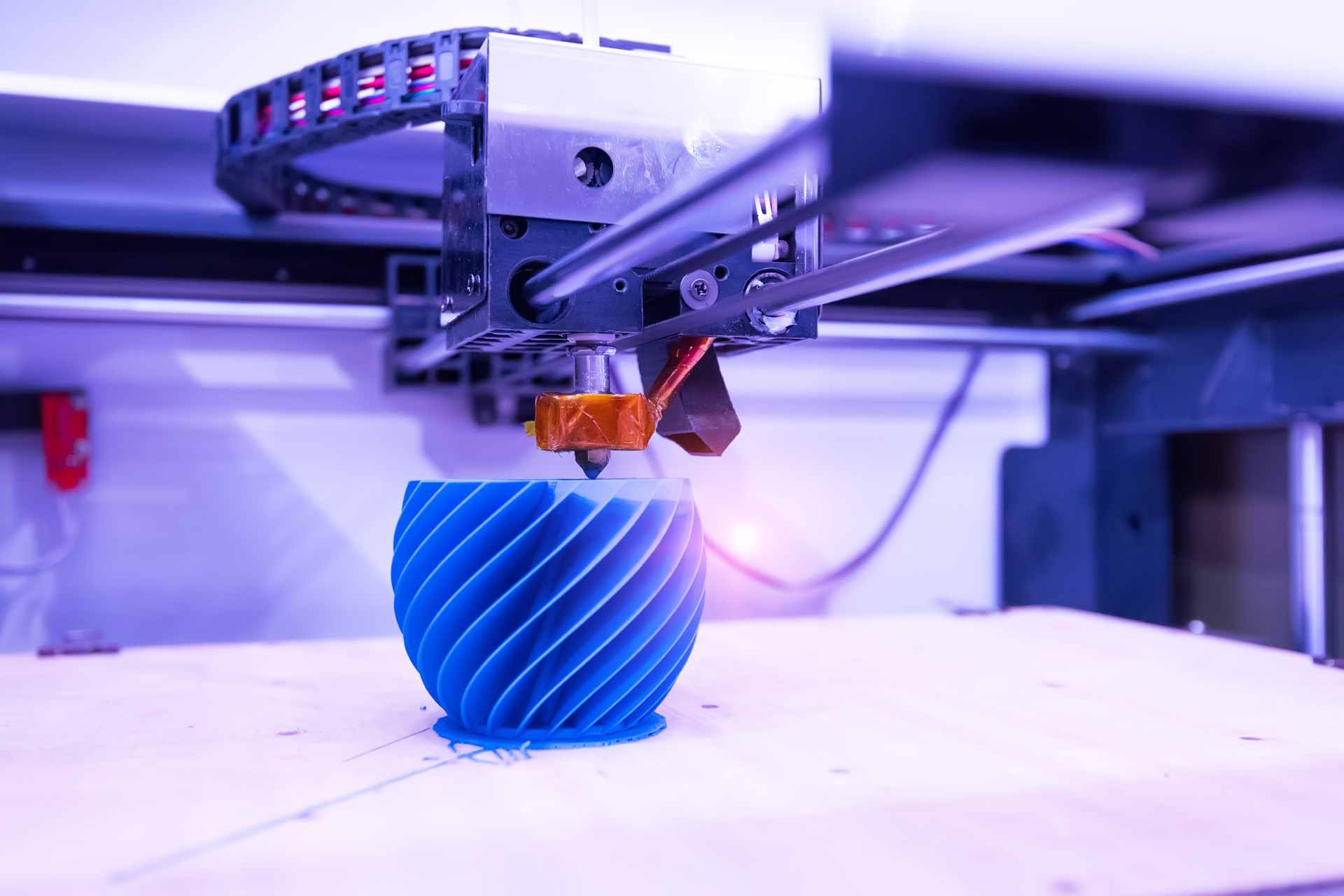

Ceramic 3d Printing Process for Technical Components

The evolution of 3D printing technology has ushered in a new era of manufacturing, where precision, efficiency, and innovation converge. Among the diverse materials now being harnessed in this domain, ceramics stand out for their unique qualities and the specialized process required to mold them into complex, technical components. Unlike traditional manufacturing methods, ceramic 3D printing offers unparalleled flexibility and precision, making it a game-changer for industries requiring components with high durability and exacting specifications.

How Ceramic 3D Printing Works

Ceramic 3D printing offers a unique additive manufacturing (AM) technique for producing complex, near-net shape components from ceramic materials. Unlike traditional manufacturing that often subtracts material, 3D printing adds material, using a layered approach to build three-dimensional objects from a digital design file.

There are several techniques in ceramic 3D printing, including Stereolithography (SLA), Digital Light Processing (DLP), and Binder Jetting. Each technique uses a different approach to transform a ceramic powder or resin into a solid object.

- SLA (Stereolithography) and DLP (Digital Light Processing): Both SLA and DLP utilize light to solidify a mixture of ceramic particles and photopolymer resin, layer by layer. SLA employs a laser for precise control, while DLP projects an entire layer image at once for faster printing. These methods are ideal for creating intricate shapes with fine details.

- Binder Jetting: This technology works by depositing a liquid binding agent onto layers of ceramic powder. The binder selectively glues the powder particles together, forming the desired object. Binder jetting is highly efficient for producing large or complex components.

Step-by-Step Guide to the Ceramic 3D Printing Process

This guide outlines the journey from a digital model to a tangible, high-quality ceramic component.

1. Design Preparation

The first step involves creating or obtaining a 3D model of the desired component using CAD software. This model is then converted into a format compatible with the 3D printer, typically STL (stereolithography) format, which slices the model into thin, printable layers.

2. Material Selection

Depending on the application, appropriate ceramic materials are chosen for its specific properties like heat resistance or mechanical strength. Common choices include:

- Alumina (Aluminum Oxide): This material boasts high strength and excellent thermal conductivity, making it perfect for electronic substrates and heat sinks.

- Zirconia: Known for its high fracture toughness and wear resistance, zirconia is well-suited for mechanical parts and dental implants.

- Silicon Carbide: This material excels in high-temperature applications due to its impressive thermal conductivity and chemical stability.

3. Printing Process

- For SLA and DLP, the printer’s build platform dips into a tank of liquid ceramic resin. A laser or projector then hardens the resin layer by layer according to the CAD model.

- In Binder Jetting, a thin layer of ceramic powder is spread across the build platform, and a print head deposits a liquid binder at specific locations to form each layer of the object.

4. Debinding

Some processes require a debinding stage, where the printed object is placed in a chemical bath or heated to remove any remaining resin or binder, leaving behind a ‘green part’—a part that is shaped correctly but not yet sintered for strength.

5. Sintering

The green part is sintered in a kiln at high temperatures below the ceramic’s melting point. This process burns off any leftover organic materials and causes the ceramic particles to fuse together, creating a dense and strong final product.

6. Post-Processing

Depending on the requirements, the sintered component might undergo additional processes, such as machining, glazing, or polishing, to achieve the desired surface finish or dimensional accuracy.

Benefits & Applications of 3D Printed Ceramics

The integration of 3D printing with ceramics has introduced a plethora of advantages, particularly for components that demand high precision, durability, and material efficiency. Let’s delve into some of these benefits and application examples:

Design Freedom and Complex Geometries

3D printing empowers designers and engineers with the unprecedented capability to manufacture parts with complex geometries that would be difficult, if not impossible, to create using traditional methods. This level of design freedom allows for the optimization of components for improved functionality and efficiency. For instance, intricate cooling channels can be integrated into parts for aerospace engines, enhancing performance while maintaining strict weight controls.

Superior Material Properties

Ceramics are renowned for their exceptional properties, including resistance to high temperatures, wear resistance, and chemical stability. These characteristics make 3D printed ceramic components ideal for applications that require durability in extreme conditions. In the world of high-performance automotive engineering, ceramic brake discs and engine components exemplify how these superior material properties can be leveraged for unmatched performance and longevity.

Lightweighting and Part Consolidation

3D printing facilitates the production of lightweight components without compromising strength or durability. Consolidating multiple parts into a single, more efficient design helps manufacturers reduce assembly time, enhance part performance, and lower production costs. The aerospace industry benefits greatly from this, where every gram saved can contribute to fuel efficiency and overall aircraft performance.

Applications of Ceramic 3D Printing in Industries

Ceramic 3D printing’s adaptability and high-performance material traits are increasingly being harnessed across various sectors, propelling advancements and solving intricate engineering challenges.

- Aerospace: This sector utilizes ceramic 3D printing for crafting parts like turbine blades and heat shield panels, capitalizing on the thermal resistance of ceramics to minimize failure risks in extreme conditions.

- Medical: Leveraging ceramics for their biocompatibility, the medical industry creates custom implants and surgical tools, with materials such as zirconia being used for bone substitutes and dental implants, offering personalized, durable solutions.

- Automotive: The automotive industry adopts ceramic 3D printing for engine and braking system components that require high wear resistance, thus enhancing vehicle performance and longevity.

- Electronics: In electronics, ceramic 3D printing is pivotal for producing insulators, substrates, and heat sinks, benefiting from ceramics’ electrical insulation and thermal conductivity to boost device efficiency and reliability.

- Energy: For the energy sector, 3D-printed ceramics are integral to fuel cells and batteries, where their chemical stability and thermal management capabilities lead to more sustainable, efficient energy solutions.

Transforming Technical Components with Smartech’s Custom 3D Printed Ceramics

As innovation leaps forward, the manufacturing landscape is being reshaped by the potential of ceramic 3D printing. Its unique ability to deliver extraordinary precision, creative liberty, and exceptional material characteristics sets a new benchmark. Smartech, in collaboration with Steinbach’s Technical Ceramics, is at the vanguard of this transformation, offering Custom 3D Printed Ceramic Components that lead the industry.

Choosing Smartech means access to our Lithography-based ceramic manufacturing (LCM) technology—a pinnacle of precision, creating components that are not just lightweight and resilient to high temperatures but engineered to an unrivaled degree of accuracy. This advanced method surpasses traditional 3D printing, propelling both your prototypes and mass production into a new era.

The leap to ceramic parts can be daunting, considering the high cost of equipment and the expertise required. Why plunge into deep waters when you can test the temperature with Smartech? Whether it’s for a handful of prototype parts or scaling to a run of thousands, Smartech provides an affordable, swift, and expert solution, eliminating the need for hefty initial investments in machinery and specialized staff. Take the first step towards integrating cutting-edge ceramics into your product design without the overhead of owning the complex machinery.

Ready to witness the impact without the imprint of high costs? When starting the innovation of your product by using ceramic parts you just need to call Smartech and ask for a quote!

Looking for More Information?

Check out our Resources or Contact Us