Thermal and Acoustic Insulation’s Specific Industries

Thermal and Acoustic Insulation

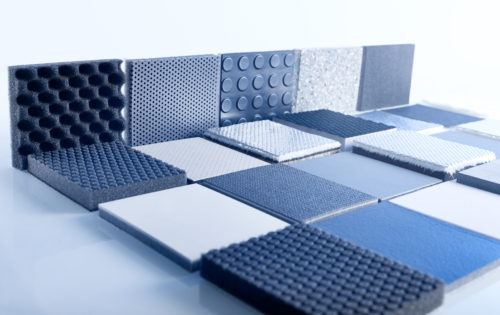

We have teamed up with Steinbach of Germany as well as AluThermo of Belgium to offer a wide range of thermal and acoustic insulation products and ceramic insulators, too. Steinbach is known as one of the leading manufacturers with custom-designed and custom-cut insulation materials.

Steinbach is known as one of the leading manufacturers with custom-designed and custom-cut insulation materials. Their decades of experience, excellent quality, and superior service combine to save our customers time and increase their product’s value. From design through customization and delivery, our partnership ensures that every customer receives the highest quality materials and seamless service.

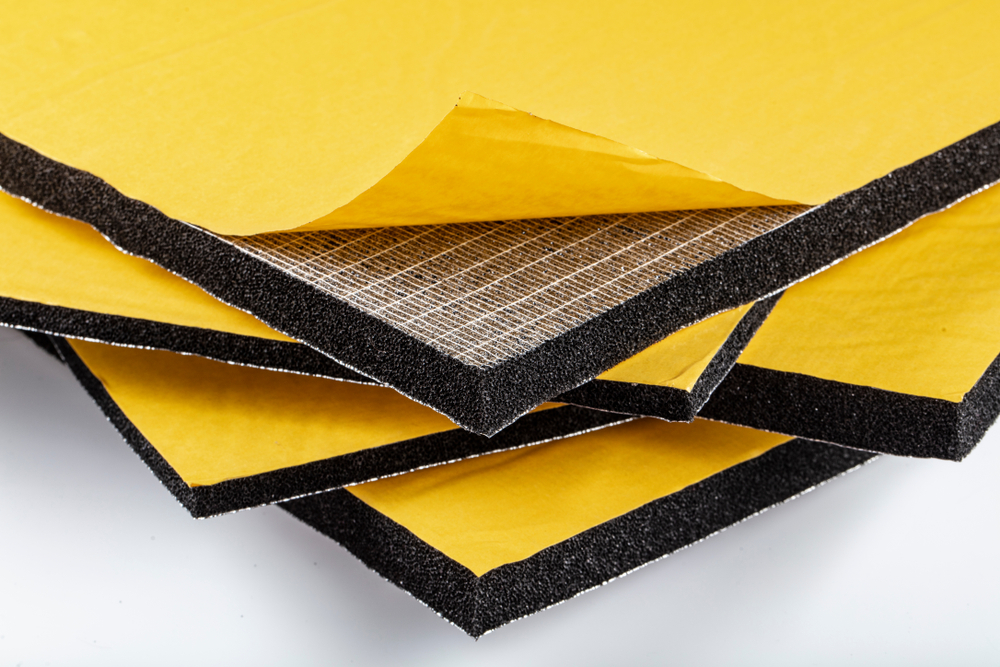

Smartech introduces Belgian QUATTRO Insulation to the US Market

AluThermo’s QUATTRO insulation is a new option for both commercial and residential construction. QUATTRO combines layers of aluminum, self-extinguishing polyethylene bubbles, and fire-retardant polyethylene foam into a 7-layer lightweight insulation that is up to 13% more effective than mineral wool insulation. QUATTRO can be used for all roof, floor and wall applications. At only 0.4″ thick and approx. 22 oz per square yard, QUATTRO is both easy to handle as well as versatile. QUATTRO can serve as an all-in-one insulation, vapor barrier, and roof membrane. Contact Martin Jansen at MJansen@SmartechOnline.com or 650-399-5516 for a sample today!

Uses of Thermal and Acoustic Insulation

Thermal and acoustic insulation can be used in a number of industrial and commercial applications to reduce sound and heat. These include the following:

• Pipe and valve enclosures

• Machine enclosures

• Flooring

• Doors

• Automotive and equipment panels

• Engine bays

Why Thermal and Acoustic Insulation Is Necessary

While it’s not something people see or even consider, thermal and acoustic insulation is used in a wide number of locations. If heat and noise are not considered and dealt with, they can place employees and others at risk. Engines produce a large amount of heat and sound that can damage the human eardrum and make people uncomfortable. At high enough levels, they can violate standard safety regulations. Heat can also cause damage to other production components, including electronics, and lead to overheating. For example, large diesel engines without insulation can produce so much heat that the vehicle’s on-board electronics fail.

How Thermal and Acoustic Insulation Work

Thermal insulation is designed to reduce or eliminate the amount of heat that is transferred between objects of differing temperatures. Heat always flows from the hotter object to surrounding cooler areas. However, not all materials conduct heat at the same rate. By using an insulator with a low thermal conductivity, heat is transferred at a lower rate. Acoustic insulation works by redirecting or absorbing sound waves. These waves are created by vibrations that travel through the air on specific frequencies.

How to Select the Correct Insulation

There are a number of factors to consider when selecting the correct thermal and acoustic insulation. Heat is transferred via three different methods: convention, conduction, and radiation. Convection transference is done through the air, while conduction is via touch or direct contact. Radiated heat is transferred through infrared waves. Some insulating materials are better than others at slowing down each type of heat transfer. For example, aluminum foil is effective at insulating against radiated heat, while fiberglass is a better option for convection and conduction heat transfer.

For acoustic insulation, the correct insulation depends on whether you need to reduce the noise that is inside a building or on the outside. For outdoor environments, you want insulation that reflects or dampens the vibrations in the air. For interior acoustic insulation, look for materials that absorb the sound rather than redirect it. The material’s cellular structure plays a part in this. The porosity of the material, its cell size, and its density and thickness all determine how effective it is at reducing noise.

Contact Us Today to Learn More

Call us today and tell us your functional requirements, geometry, quantities and packaging, and let the Smartech team design the best solution for your needs.

Looking for More Information?

Click the button below or get in touch with one of our locations