Silicone and Rubber Membranes for Woodworking Vacuum Presses

Smartech’s roots in the woodworking industry go back over 30 years, with support for many well-known manufacturers as well as smaller shops that need fast help and dependable supply. When a vacuum press membrane matches your temperature, part geometry, and finish target, you get consistent pressure, repeatable cycles, and cleaner surfaces with less scrap and less rework.

Silicone and Rubber Membranes for Woodworking Press Applications

In woodworking vacuum presses and membrane presses, the diaphragm controls how pressure transfers through veneers, foils, laminates, and layups. The right membrane helps maintain even contact across edges, contours, and routed details so parts release cleanly and finishes stay uniform.

Common uses include:

- Veneer pressing on flat panels and gentle contours

- 3D lamination on routed MDF doors, drawer fronts, and contoured components

- Thermoforming and membrane press cycles where heat and stretch repeat across production runs

- Short-run work where switching parts quickly matters, and tooling needs to stay flexible

Silicone Membranes for High Temperature Woodworking Press Cycles

Silicone membranes are a strong fit when your press runs elevated heat, when cycles repeat frequently, or when you need stable elasticity across long runs. Silicone is often selected for 3D lamination and forming work where release, stretch, and surface quality must remain consistent across multiple cycles.

For press temperatures over 120°C (248°F), silicone grades are recommended.

Natural Rubber Membranes for Veneer Pressing and Deep Contours

Natural rubber membranes provide high tear resistance and a soft contact surface that supports real wood veneer and deep contours. The matte finish can reduce visible scuffing and works well with high gloss foils and coatings in many woodworking setups.

Natural rubber is commonly used at moderate press temperatures, and press temperature is often determined by the adhesive system, so the membrane and glue need to work well together.

How to Choose a Woodworking Vacuum Press Membrane

Membrane selection usually comes down to four practical factors that affect forming, surface quality, and service life.

Durometer and Forming Performance

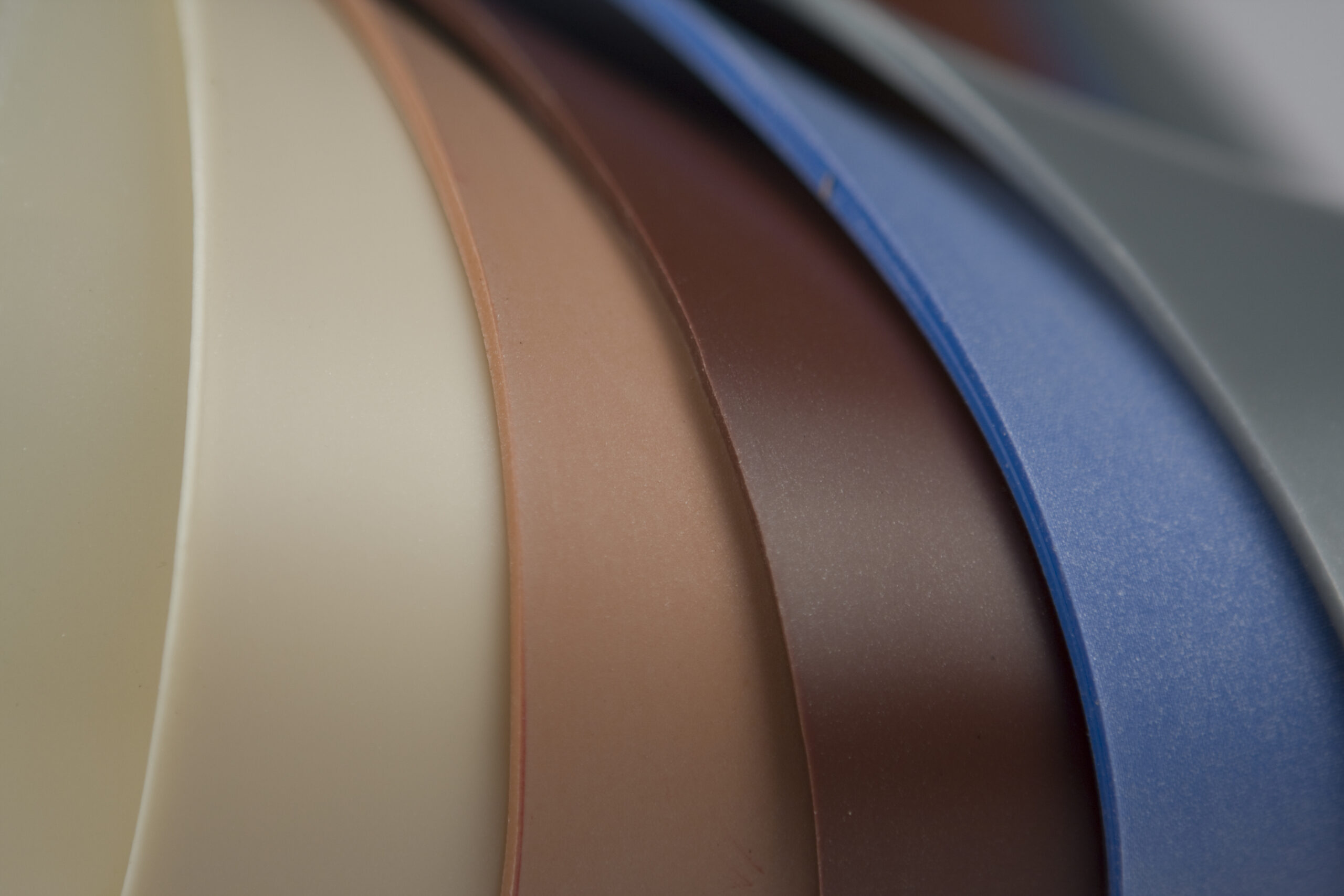

Durometer measures hardness. Softer grades conform to deeper profiles and delicate veneers. Firmer grades often suit flatter parts and can extend membrane life. Color does not change performance. Manufacturers often use color to help identify grade and thickness quickly.

Smooth Vs Textured Membrane Surfaces

Smooth surfaces are commonly chosen for high-gloss foils and sensitive finishes. Textured silicone can reduce scuffs and shadows, limit memory effect marks on sharp edges, and release from 3D laminate more easily due to its lower friction coefficient.

Press Temperature and Adhesive Compatibility

Match the membrane material to peak press temperature and adhesive vapors. Silicone generally withstands higher temperatures and more aggressive chemicals than natural rubber.

Membrane Thickness And Sheet Size

Thinner sheets stretch over deeper forms. Thicker sheets increase durability. Smartech can help match cut sizes or rolls to many press brands and common woodworking press formats.

Most Popular Silicone and Rubber Vacuum Press Membranes for Woodworking

These membrane grades are common for woodworking presses, covering veneer, foils, and 3D lamination. Share your press model, temperature range, adhesive, and part geometry, and Smartech can recommend a starting option and reduce trial and error.

Woodworking Vacuum Press Membrane FAQs

Does membrane color affect performance?

Color mainly helps identify grade such as durometer. Similar colors across brands do not guarantee the same performance.

Should I use a smooth or textured membrane?

Smooth surfaces often suit high gloss foils and sensitive finishes. Textured or matte surfaces can reduce visible scuffing, adjust sheen, and help release on 3D laminate work.

When should I use silicone instead of natural rubber?

If your press temperature goes over 120°C 248°F, silicone grades are recommended. Silicone is also commonly chosen when you want stable elasticity through repeated heated cycles.

How long do vacuum press membranes last?

Service life depends on temperature, geometry, tooling, and handling. In well managed presses, many installations run through hundreds of cycles or more.

Looking for More Information?

Check out our Resources or Contact Us