Specific Industries for Silicone & Rubber Membranes

Steinbach silicone membranes and natural rubber membranes are built to deliver consistent pressure, repeatable cycles, and clean surfaces, while Smartech helps you match each press to the right material, thickness, and surface finish so production stays efficient and predictable. Smartech and Steinbach have partnered to support demanding processes with membrane options that balance flexibility, durability, and reliable results, with inventory on hand to keep downtime to a minimum.

Why manufacturers choose these membranes

- Fast delivery from stocked inventory since Smartech keeps hundreds of Steinbach membranes on hand

- Surface options that match your finish goals

- Smooth silicone and matte natural rubber for smooth, high-gloss results

- Textured silicone to reduce scuffs and shadows, limit memory effect marks on sharp edges, and release from 3D laminate more easily due to a lower friction coefficient

- Flexible, durable construction designed for industrial production demands

- Selection support that reduces trial and error since the best membrane depends on how it will be used, not on a one-size-fits-all recommendation

Steinbach Silicone And Natural Rubber Membranes

Steinbach membranes are engineered for flexible operation, reliable sealing, and long-running performance in industrial vacuum presses. You can choose from multiple grades of silicone membrane and natural rubber to support both automated lines and smaller custom shops that depend on steady throughput.

Have questions about which membrane best supports your parts, temperatures, and adhesive system? Call 704-362-1922, and our team can help you select the right option for your process.

Silicone Membranes For High Temperature Pressing

Steinbach AG of Detmold, Germany, works closely with 3DL component producers, vacuum former manufacturers, and membrane press experts to produce high-quality membranes for woodworking and other demanding press applications. Whether you call it a membrane, a bladder, or a diaphragm, Steinbach is a leading option for consistent performance.

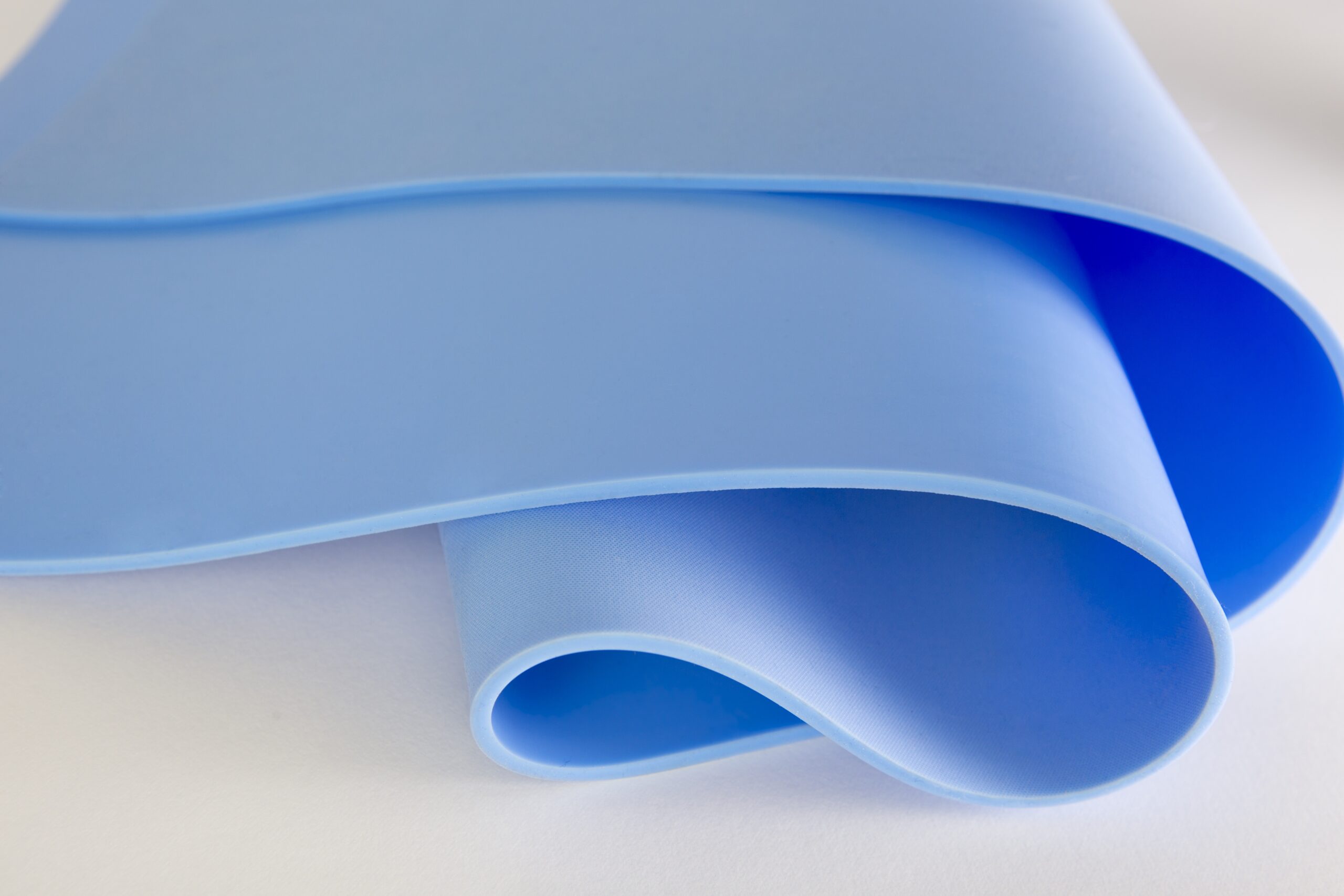

Steinbach silicone membranes handle higher temperatures than natural rubber and maintain elasticity through repeated cycles, making them well suited for 3D lamination, thermoforming, solar module production, and glass lamination where elevated heat is required. Many silicone membrane sheets can replace an original diaphragm without hardware changes, and they’re built to last through hundreds or even thousands of pressing cycles when parts are properly spaced and well-designed, with multiple elongation options available to match your process.

Natural Rubber Membranes For Veneer And Contours

Steinbach natural rubber membranes provide higher tear resistance along with a soft contact surface that supports real wood veneer and deep contours. The matte finish helps reduce scuffing and performs well with high-gloss foils and coatings. Natural rubber runs at moderate press temperatures, but for temperatures over 120°C (248°F), silicone grades are recommended. Because press temperature is often determined by your adhesive, make sure your membrane and glue will work well together.

Choosing The Right Membrane For Your Press

Membrane selection starts with your application details and press design. The best fit usually comes down to four factors that influence forming, surface quality, and service life.

Durometer

Durometer is an international standard that measures how hard the rubber is. It’s tested with a small device that makes an indentation, then reported as a whole number from 5 to 100 with ±5 tolerance, so a 50 durometer membrane typically falls between 45 and 55. Softer grades conform to deep profiles and delicate veneers, while firmer grades suit flatter parts and can extend membrane life in those setups.

- Type A for soft rubber

- Type D for hard rubber

- Type 00 for sponge and foam

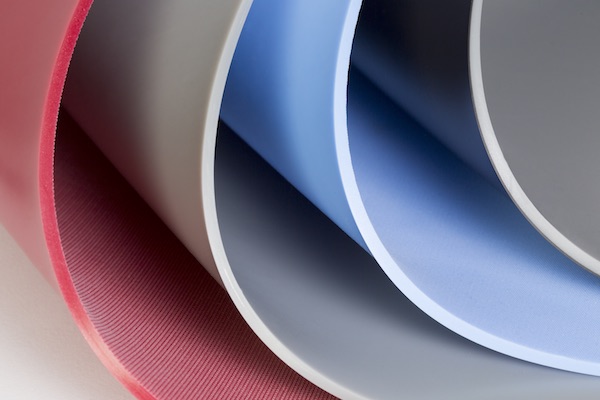

Color has no impact on performance. It’s used to indicate durometer, making it easier to identify the membrane grade at a glance and easier to tell thickness at a glance.

Surface Finish

Surface finish affects release and appearance. Smooth silicone membrane and rubber surfaces support high-gloss finishes. Textured or matte surfaces can help release parts, reduce visible scuffing, improve heat transfer in some setups, or shift the final sheen. One option isn’t inherently better. It depends on your needs and how the membrane will be used.

Temperature And Chemistry

Match the membrane material to peak press temperature and adhesive vapors. Silicone grades handle higher heat and aggressive chemistries better than natural rubber.

Thickness And Size

Thickness influences both stretch and durability. Thinner sheets stretch over deeper forms, while thicker sheets increase durability. Cut sizes or rolls can be matched to many press brands.

3D Lamination With Silicone And Rubber Membranes

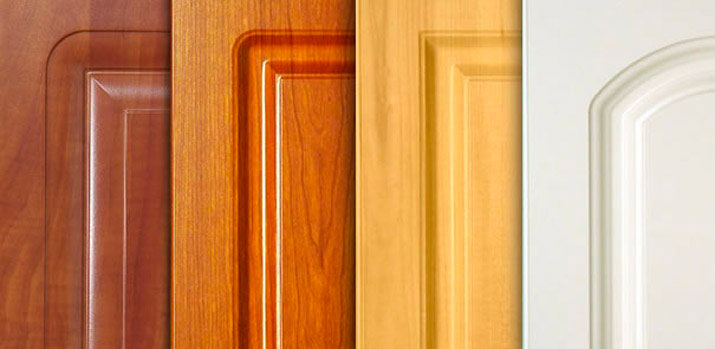

3D lamination is a process that wraps decorative foil over routed MDF so edges and contours are fully covered, creating a surface that does not require edge banding or T-molding and avoids visible seams. This makes it a strong fit for parts that aren’t completely flat or are contoured in a way that standard lamination can’t handle.

In this process, a heated silicone membrane or rubber membrane pulls the foil tight and applies uniform pressure, helping produce even pressure, strong bonds, and a smooth, seam-free finish on cabinets, fixtures, and other frequently cleaned components. It can also create aesthetic visuals that resemble wood and other surfaces, while providing outstanding durability and affordability.

Benefits of 3D lamination include

- Unparalleled flexibility

- Very affordable, with a practical solution for applications that once would have required a much larger budget

- Water resistant

- Mold-resistant

- Easy to clean

- Very durable

- Works well across a wide number of commercial spaces

If you’re looking for rubber membranes for 3D lamination projects, Steinbach is a dependable option. Contact us today to discuss your project, and we can help you find the right rubber sheet membrane.

Silicone And Rubber Membranes FAQs

What difference does color make?

Color mainly helps identify durometer and product grade. Each manufacturer uses its own system, so similar colors do not guarantee the same performance.

Which surface is better, smooth or textured?

Smooth surfaces suit high gloss foils and sensitive finishes. Textured or matte surfaces help reduce scuffing, adjust sheen, and support stable heat transfer.

How long do membranes usually last?

Life depends on temperature, geometry, tooling, and handling. In well-managed presses, many Steinbach silicone membrane and natural rubber installations run through hundreds of cycles or more.

Read: How to Extend the Lifespan of Silicone Rubber Products

What information helps when selecting a membrane?

Press type, working temperature, adhesive, part shape, and finish targets are key. Sharing those details lets Smartech recommend a silicone membrane sheet for vacuum press or a natural rubber option that fits your application and budget.

Woodworking

Smartech’s roots in the woodworking industry go back over 30 years and we’re proud to list many of the industry’s most prominent names as our longtime and loyal customers. Smaller shops also know that service comes first at Smartech, and they can rely on receiving our VIP treatment every time they call. See for yourself – our excellent products and superior service will lower your production costs and improve your bottom line.

Learn moreComposites

The composites industry has discovered the versatility of Steinbach's super flexible and reusable membrane materials. They save labor time and cost, don't require extensive training, and can be used over and over again for different shapes without retooling.

Learn moreSolar

Steinbach demonstrated their commitment to the solar industry by developing the patented Lamibran® Diaphragm that stays flexible for thousands of cycles even when exposed to caustic EVA vapors. Then they developed laminator-specific mixtures to provide the best product for specific applications.

Learn moreGlass Lamination

Steinbach's vacuum bags for glass lamination ovens are both durable and have the elongation needed for flat glass panel lamination.

Learn moreDye Sublimation

Steinbach's membranes for dye sublimation provide both the durability and temperature resistance of this demanding industry.

Learn moreSteel Rule Die

Steinbach’s 2mm thick Natural Rubber Membrane is a popular replacement for Gerber and other steel rule die vacuum presses. With or without mounting holes – these durable membranes have been the go-to in the industry as a reliable and affordable alternative to the OEM replacement membranes.

Learn moreLooking for More Information?

Check out our Resources or Contact Us